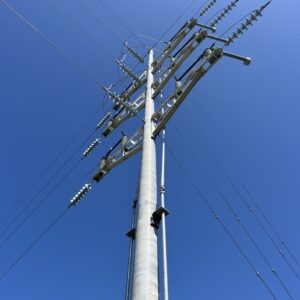

Don’t settle for Ductile Iron. Stand tall with Spun Concrete.

Something has to change

According to the American Society of Civil Engineers’ 2025 report card[1], the United States received a C for their infrastructure, indicating a mediocre system that requires attention. Even more alarming, the United States received a D+ for the energy sector, indicating that the system is poor and at risk for failure. With more than 80% of electricity outages caused by weather events since 2000, decision-makers are continuously seeking out modern technologies and grid-hardening solutions in hopes to improve the system.

Today, decision-makers are actively taking the first steps into creating a stronger grid – one step being to seek out resilient materials for utility poles. Unfortunately, such a task is not easy as multiple factors must be taken into consideration.

- What is the expected service life of a pole?

- What is the durability of a pole?

- What is the process of installation?

- How often is maintenance required?

- What customization options are available?

With these questions in mind, two materials often seen in the marketplace are considered -ductile iron and concrete. Both are made from environmentally friendly materials and have shown to have a long service life, yet there are a few differences between the two.

Installation

Many consumers are not aware that the installation of ductile iron poles, if done incorrectly, can cause damage to the pole. Most ductile iron poles are shipped fully assembled; however, depending on the height, poles may be shipped in two pieces. Poles shipped in two pieces require binding of the parts, which can result in damage to the pole.

With StressCrete’s spun concrete poles, all poles are a single, continuous unit, resulting in an easy-to-install application.

Customization

With ductile iron poles, consumers are limited in customization. For example, for consumers needing to specify a pole with more than 20 through-holes, an additional charge will be applied. Ductile iron poles also come in few coated finishes – gray, black, and brown.

At StressCrete, our spun concrete poles are designed to meet your specific needs including length, strength, and other applications such as mounting holes, apertures, grounding, and much more. StressCrete also offers multiple décor colors for consumers to choose from such as Midnight Lace, Salt and Pepper, and Autumn Red; to blend into the surroundings or make a statement. The color is throughout the pole itself, instead of applied as a coating, resulting in a vibrant color that lasts for years to come.

Corrosion

With ductile iron poles, a ceramic epoxy coating is applied to every pole to protect ductile iron against waste pipe applications and potential corrosion. Ductile iron poles also offer an optional ‘bare’ or ‘weathered’ coating that can extend a pole’s service life in more weather-active areas. However, this additional coating can be costly.

With StressCrete’s spun concrete poles, no additional coatings are needed to withstand the elements, resulting in a corrosion-free solution.

How to Specify

Explore the various classes available and how spun concrete can support your project’s load.

Utility Pole Brochure

Check out a ‘behind the scenes’ look into our production process, application types, and benefits of using spun concrete poles.

.

Utility Pole Comparison Chart

Check out how other popular materials in the industry compare to spun concrete.

Case Study

The City of Keosauqua, Iowa was frustrated by the constant cycle of repairs and replacements required to maintain their system of distribution lines on wood poles. See how StressCrete provided a solution.

Contact

Interested in learning more about our utility pole offerings? Or looking to talk to a local sales rep about an upcoming project? Contact us today!

[1] American Society of Civil Engineers. (2025). Energy Infrastructure. ASCE’s 2025 Infrastructure Report Card. https://infrastructurereportcard.org/cat-item/energy-infrastructure/