SUMMARY

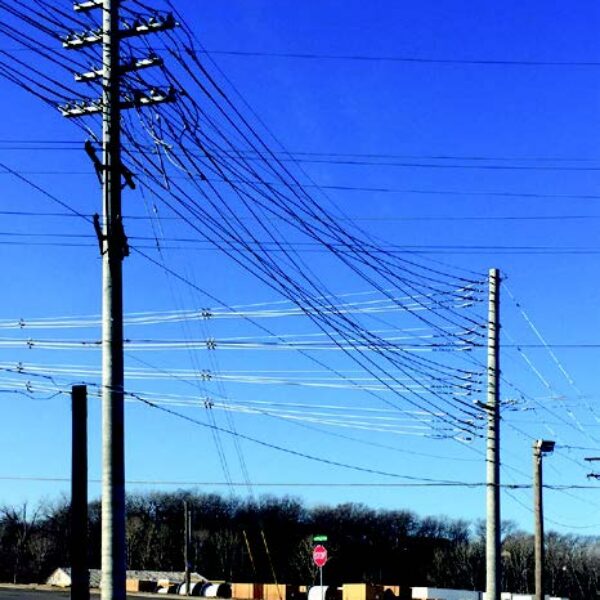

Kansas City Board of Public Utilities (BPU), a publicly owned and self-governed administrative agency of the Unified Government of Wyandotte County/Kansas City, Kansas, has been providing electric service to homes and residences since 1912. Today, the utility’s electric system serves 65,000 customers covering over 127 square miles with two active power stations, 29 substations and 4,000 miles of electrical lines. The utility’s electric system has been recognized as one of the country’s most reliable and safe electric utilities. For 2018, two of BPU’s major goals and priorities include providing cost effective, safe and reliable utility services, as well as maintaining and updating infrastructure as needed.

Download Case Study (PDF)PROJECT HIGHLIGHTS

Project Site: Kansas City, Kansas

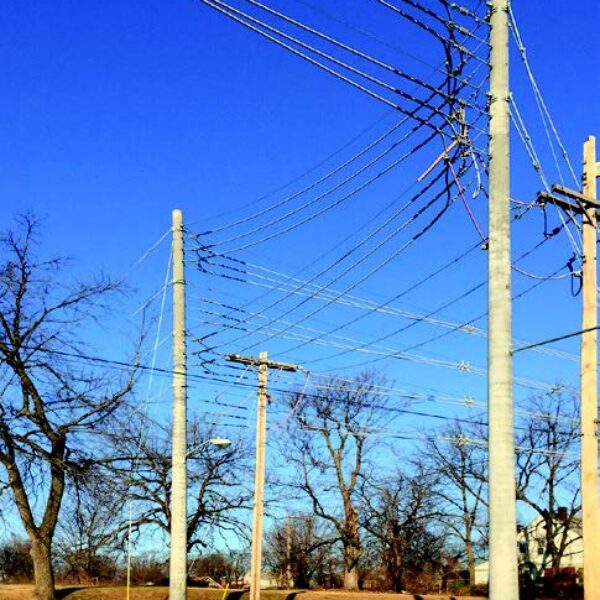

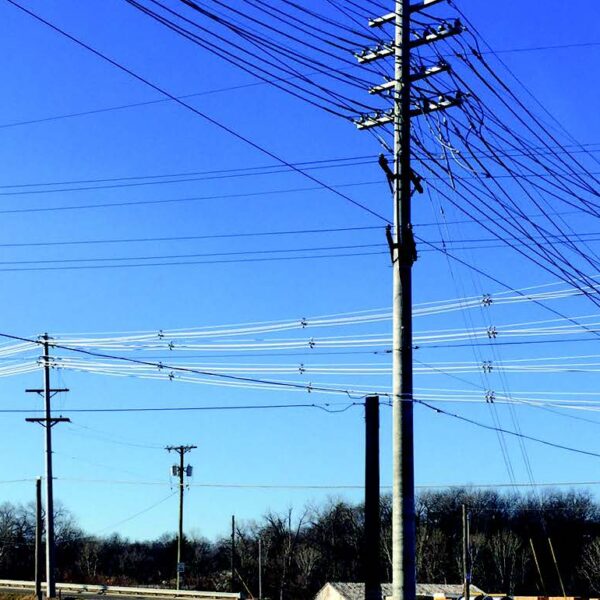

Infrastructure Upgrade: 285 StressCrete prestressed spun concrete poles ranging from class G through P (class 1 through H8 wood pole equivalents) were installed for higher pole height, greater strength and increased load capacity. These poles replaced lower classed wood poles which due to their age, limited strength and shorter length were unable to withstand future growth requirements.

Spun Concrete Benefits:

- Increased reliability

- High strength and durability

- Cost effective due to long service life, maintenance free and lifetime warranty

BPU SELECTED PRESTRESSED SPUN CONCRETE UTILITY POLES TO INCREASE RELIABILITY

RELIABILITY IMPROVEMENTS TO WITHSTAND FUTURE GROWTH REQUIREMENTS

With reliability as one of BPU’s main priorities, the Board of Directors continually seeks to improve its electrical system. One of BPU’s challenges over recent years has been to improve service, longevity and overall system hardening of electrical service from the Fairfax industrial area to downtown Kansas City with the existing infrastructure. Another challenge has been the development of a new Amazon warehouse and distribution center in Kansas City, where much thought was put into ensuring reliability for this new industrial customer with respect to power and back-up systems.

To address these challenges, plus with the construction of the new Fiberglass substation in the Fairfax industrial area and the expansion of services to new industrial customers, BPU methodically evaluated the best, longest lasting method of distributing power throughout the industrial areas and to the downtown area. Throughout this process, BPU determined the existing wood poles needed replacement as they simply did not offer the strength capacity for future circuits including communication and street lights. Thus, an engineered long-lasting distribution pole was needed.

INFRASTRUCTURE UPGRADED TO SPUN CONCRETE POLES

After careful cost evaluation, BPU decided to upgrade their infrastructure with StressCrete prestressed spun concrete poles due to their very long service life, no maintenance needs and lifetime warranty. The system hardening upgrade which provided higher pole heights, greater strength and increased load capacity proceeded in five phases totaling 285 spun concrete poles ranging in lengths from 35’ to 85’ and are of classes 1 through H8 wood pole equivalents.

Download Case Study (PDF)BPU is very pleased with the infrastructure upgrade using StressCrete poles. It has allowed us to improve reliability to our existing customers and provide capacity for future growth.

Jeremy Ash, Director of Electric Distribution and Services

Working on a similar project?

Get in touch with our team. Tell us more about the project you’re working on and together we will find a solution.