SUMMARY

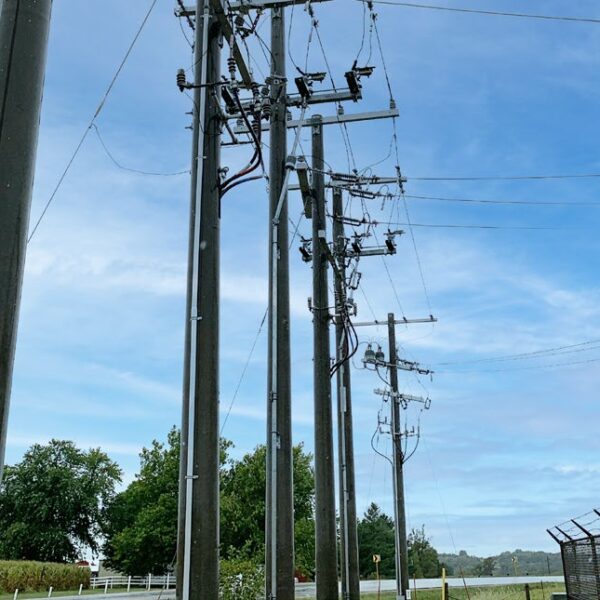

The City of Keosauqua, Iowa was frustrated by the constant cycle of repairs and replacements required to maintain their system of distribution, lines on wood poles. To reduce maintenance requirements, the City of Keosauqua Light & Power Board divided the city into 10 sections to evaluate a number of infrastructure options. With a different option per section, the testing process was underway. After completing the section using StressCrete prestressed, spun concrete poles, the Board approved the use of concrete across the whole city. Over the next 10 years, they replaced the entire distribution pole system with 334 Class E concrete poles, ranging from 30’ to 50’.

Download Case Study (PDF)PROJECT HIGHLIGHTS

Project Site: Keosauqua, Iowa

Dates: 2005 to 2015

Pole Details: 334 Class E concrete poles (Class 3 Wood Pole Equivalent) ranging between 30’ and 50’

Distribution Pole Replacement Program Becomes Enviable System Wide Upgrade

THE CHALLENGE

The City of Keosauqua is responsible for approximately 10-15 miles of overhead and underground distribution lines from two substations outside of the city. Like many municipalities, they had been using wood poles; however, they were getting increasingly frustrated by the constant maintenance that the wood pole system required. On average, the poles were being replaced every 10-15 years, in addition to the ongoing maintenance. The board decided to look into alternatives to wood poles to see if there was a better solution available.

THE SOLUTION

In an effort to improve the overall distribution system for the city, the board divided the city into 10 sections, with the intent of trying multiple solutions across different sections. The city used concrete poles for the first section and discovered many benefits to the prestressed, spun concrete pole solution. With a little bit of pre-planning, the city realized that StressCrete can manufacture the pole with all of the various configurations in place, which has reduced the installation time as crews do not need to drill into the pole on-site. They also discovered the flexibility of the option to have a universal layout with additional holes in the pole to accommodate future expansion.

THE RESULTS

For the first installation, both the city and their contractor were unfamiliar with concrete, so they were unsure of what it would require. Once they got through the first few poles, they both realized that the installation process is not any different than a wood pole, so the remaining installations were done at the same rate as wood poles. The city was so impressed with the concrete poles, they decided to convert the entire distribution system to concrete poles over a period of 10 years.

Once they are installed they are virtually maintenance free. There’s no difference in the installation of a wood pole to a concrete pole. It’s just as easy, if not easier, to install concrete.

– Stan Whitten, Electric Superintendent, City of Keosauqua

HIGHLIGHTS

Product Details:

- 334 utility distribution poles.

- Pole lengths ranging from 30’ to 50’ overall length, direct buried.

- Pole class E (Class 3 WPE).

Unique Features:

- Cable Entrance Covers provide aesthetic improvements.

- Keeps out birds.

- Utilizes interior runway of the pole instead of exterior conduit.

- Reduces number of risers as distribution to individual homes can occur below grade.

- Internal grounding.

- Rarely written up by inspectors.

Key Benefits:

- Increased reliability reduces service outages.

- Cost effective due to long service life, maintenance free, and lifetime warranty.

- Customized hole layout for ease of installation and improved future expansion.

Download Case Study (PDF)Southern Iowa Electric has begun installing concrete outside their substations after working with us because they have seen how reliable concrete poles are. They were looking for a solution that was weather resistant and virtually maintenance free for a critical section of the system.

– City of Keosauqua, Electric Superintendent

Working on a similar project?

Get in touch with our team. Tell us more about the project you’re working on and together we will find a solution.